Hard and brittle materials generally refer to quartz crystals, glass, ceramics, lithium carbonate, lithium niobate, sapphire, etc. This type of material is widely used due to its excellent properties. The research on ultra precision machining methods for hard and brittle materials will further expand their application scope and improve their performance.

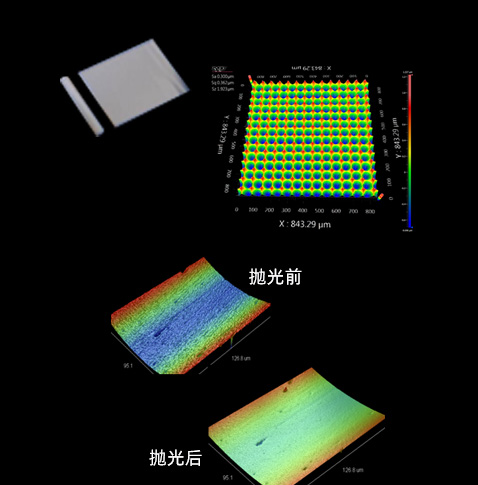

Due to the high hardness of quartz crystal stones, typical optical polishing machines are swing type, which means that the work rotates relative to the grinding disc and swings along a certain arc: the workpiece is constantly polished while also trimming the polishing mold. However, when the polishing parameters are set, the surface shape of the working and polishing molds is always in a non convergent state, that is, the surface shape monotonically changes towards the concave or convex direction. Continuously checking the surface shape and modifying the polishing parameters require high technical proficiency from the operator.

Add polishing fluid between the polishing disc and the workpiece, and use the planetary wheel to drive the movement of the workpiece. At the same time, the polishing disc provides pressure and rotational motion. With the participation of the polishing fluid, the workpiece is subjected to both chemical and mechanical polishing to achieve the effect of thinning the workpiece and achieving a better surface finish.

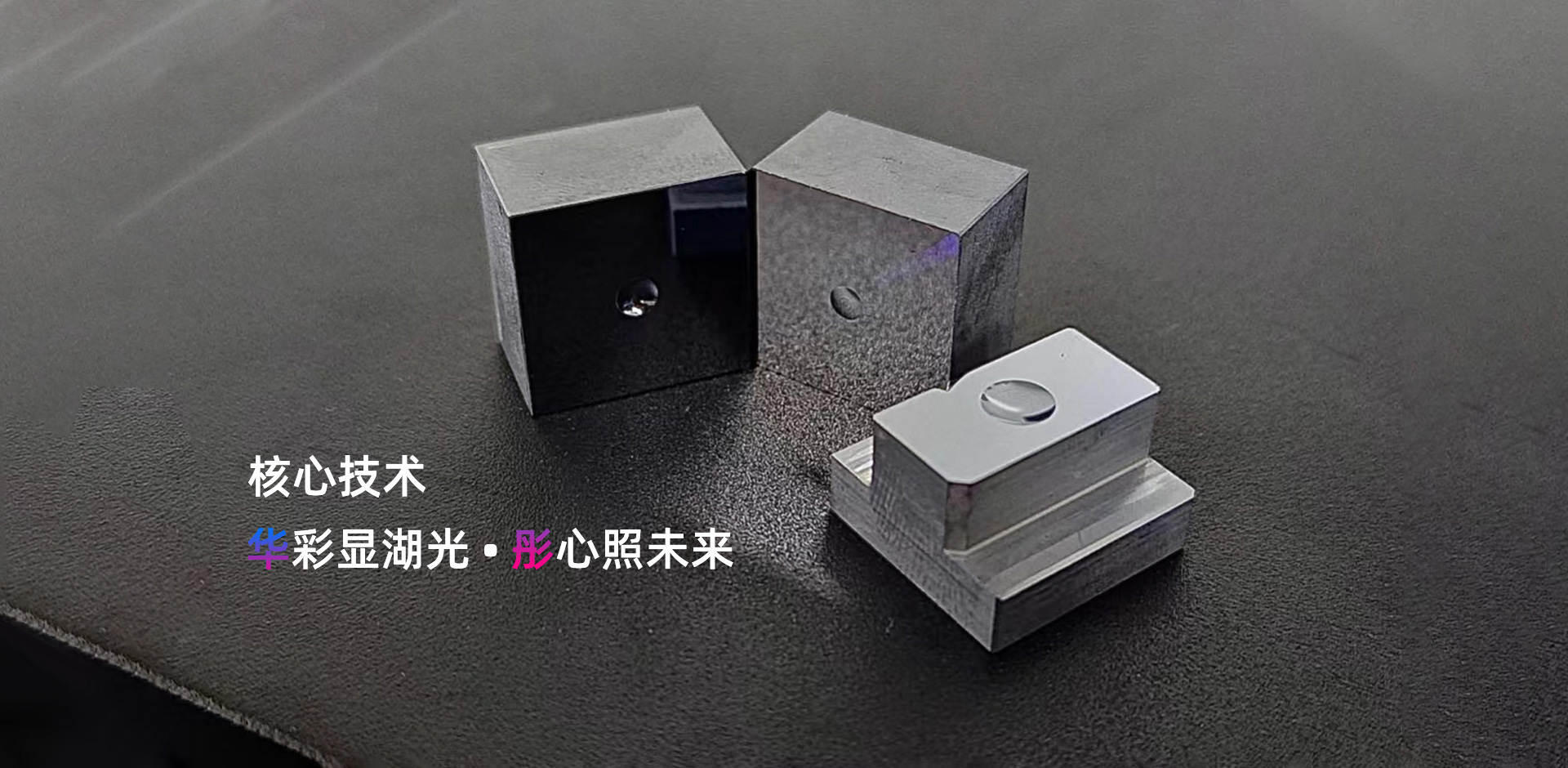

Huatong Optical Technology (Zhejiang) Co., Ltd. is a high-tech enterprise specializing in the design, research and development, and production of optical components and ultra precision machining molds. It provides optical optimal solutions for autonomous driving, medical testing and treatment, 3C industry, aerospace, ocean surveying, military industry, etc.

In the processing of hard and brittle materials, we have strong technical capabilities and complete processing techniques, including hard and brittle material thinning and surface leveling grinding, multi line cutting, polishing, photolithography and other processing techniques.

The R&D center of the company has a complete set of equipment and a professional technical team from design to processing, which can provide optical lens design and processing services for various shapes including spherical, aspheric, array, free form surface, etc. for all sectors of society.